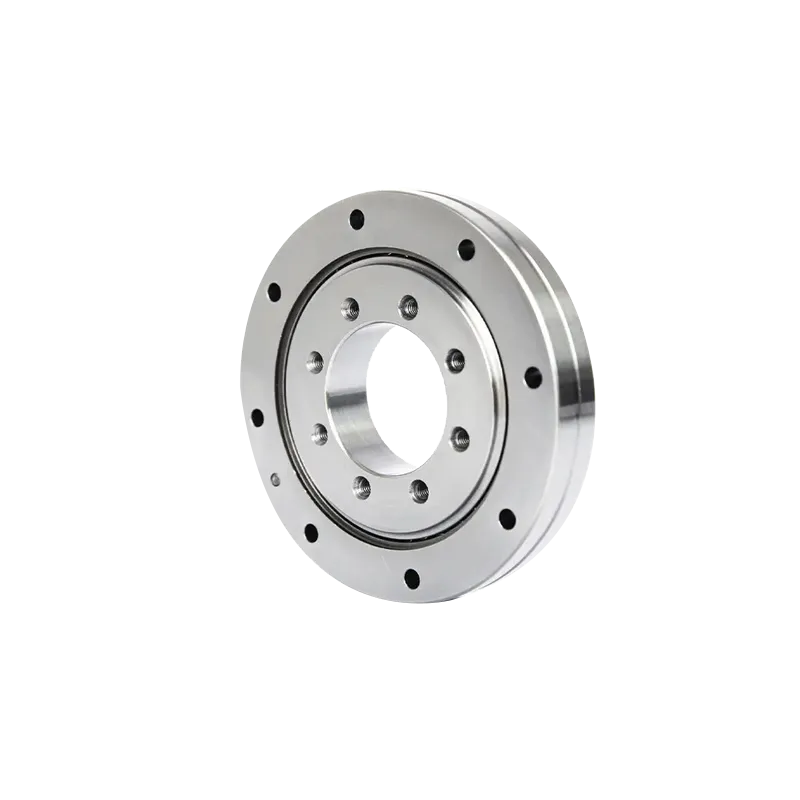

XSU type cross roller bearing (inner and outer ring integrated type) This series of models does not require fixed flanges and support seats because the mounting holes have been processed. In addition, due to the integrated inner and outer ring structure with a seat, installation has almost no effect on performance, so stable rotation accuracy and torque can be obtained. It can be used for outer and inner ring rotation. Structural features: Cross roller bearings are cylindrical rollers arranged vertically on the 90-degree V-groove rolling surface through isolation blocks, so cross roller bearings can withstand multi-directional loads such as radial loads, axial loads and moment loads. The size of the inner and outer rings is miniaturized, and the extremely thin form is close to the limit of small size, and has high rigidity, and the accuracy can reach P5, P4, and P2 levels. Therefore, it is suitable for the joints and rotating parts of industrial robots, the rotary table of machining centers, precision rotary tables, medical machines, calculators, military industry, IC manufacturing equipment and other equipment.

View Details

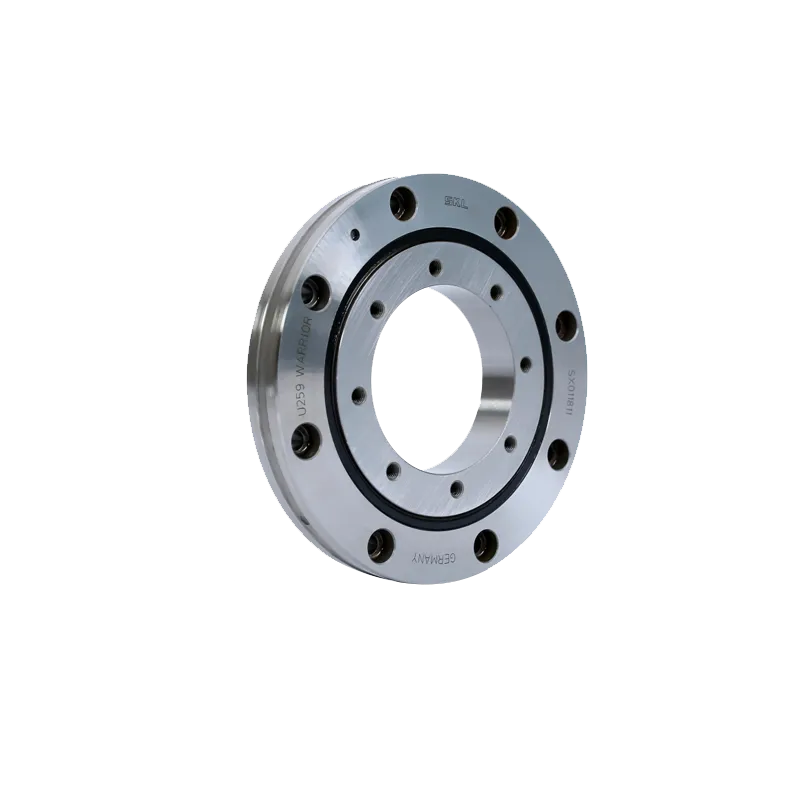

SX series cross cylindrical roller bearings are composed of outer ring, inner ring, rolling element and spacer. The outer ring is split and fixed by three fastening rings. It is suitable for high-precision occasions where the inner ring rotates. The cylindrical rollers inside the SX cross roller bearing are arranged in a cross pattern. Such a bearing can withstand axial force, radial force, overturning moment and other combined loads in two directions. Therefore, a single SX bearing arrangement can replace the design of two bearing arrangements.

View Details

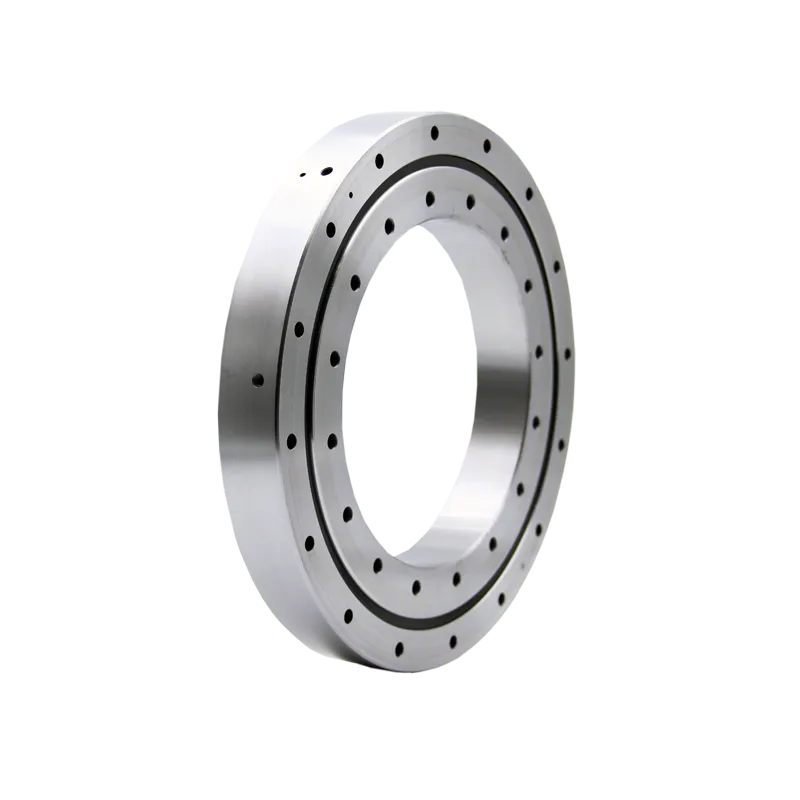

The double row cross roller bearings designed by MONTON Bearing can withstand loads in all directions, with high rigidity, high precision, simple structure and easy assembly, making them the most suitable rotating mechanism for composite machining machines. The double row cross roller bearing has installation holes on the inner and outer rings, and adopts a double row small-diameter roller design. The structure is simple and easy to install, and the bearing is directly fixed to the shaft or support seat through the installation holes. By increasing the number of rollers, high rigidity of the bearing can be achieved. The MRW type can specify the dynamic accuracy of the vibration bearing according to the machining position, measurement position, and actual working height position to meet the requirements of high rotational accuracy.

View Details