Time: 2025-08-18 06:52:29 Source: Luoyang Monton Bearing Science & Technology Co.,ltd.

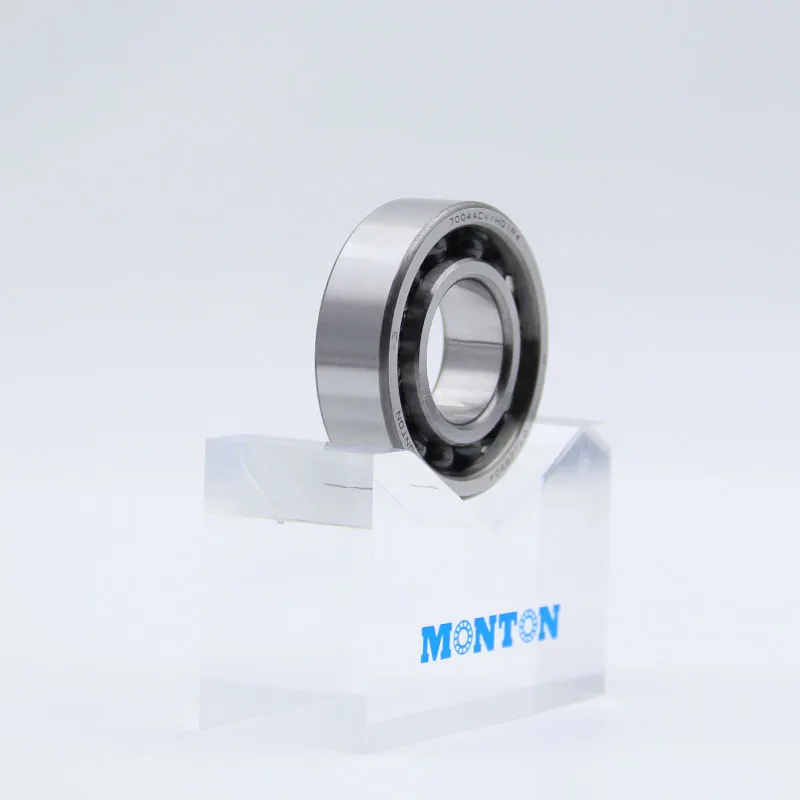

The application of hybrid ceramic ball bearings manufactured by MONTON Bearing in turbojet engines is mainly reflected in the following aspects:

1. High temperature and high-speed adaptability

The hybrid ceramic bearing adopts silicon nitride ceramic balls, which can maintain hardness at high temperatures of 400 ℃ and fail at 800 ℃, significantly better than the performance degradation problem of metal bearings at high temperatures. Its thermal expansion coefficient is small, which can effectively reduce bearing expansion deformation caused by temperature changes and adapt to the high-temperature working environment of micro turbojet engines.

The oil-free self-lubricating properties of ceramic balls enable hybrid ceramic bearings to achieve speeds up to 1.5 times that of metal bearings, solving the design requirement for turbine rotors to reach 120000 revolutions per minute. The experiment shows that it can maintain stability even after continuous operation for 5 hours, avoiding problems such as smoking and shaft holding of metal bearings at 40000 revolutions per minute.

Research has shown that the failure mode of hybrid ceramic bearings in micro turbojet engines is mainly surface metal detachment, and material optimization and structural design improvements are needed to extend their service life. Finite element analysis combined with experimental verification can effectively predict the critical speed range, providing a basis for bearing selection.